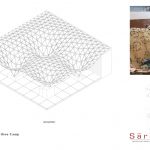

N P Pavilion | Studio Saransh | International Architecture Awards 2019

Studio Saransh was commissioned by NipponPly to design and fabricate a pavilion for Acetech Mumbai 2018, exclusively with their material. The current design is a display of the pavilion which was developed and fabricated through a process of design prototyping, structural experiments and material calibration over nine months. The shell was designed with benefits of comparably minimal wastage during the milling process, high reusability with the same precision, and ease of assembly within a days time. This design is in many ways guided and inspired by Plate Skeleton system of Sea Urchins.

The development of the form focused on communicating the client’s mission of showcasing their plywood’s innate strength. A tessellating system of triangular ‘panels’ was developed based on guided hanging chain models, achieved digitally through use of self-developed scripts and form-finding plugins like Kangaroo. One of the central concern during development of the form was to expose these panels to various kind of stresses, loads and end-conditions, so that along with being a modulating system it suffices as a marker of strength for the given material. A flat part of the shell, smooth and abrupt bends, both-side supported ends, cantilevered ends, etc were all developed to facilitate the same. Structural tests for 20kg per sq.m were conducted digitally, but the actual structure has been able to take the weight of two people simultaneously walking across it with just minor deflections.

NP Pavilion is constructed from 720 unique CNC-routed triangular plywood panels which assembles together into one continuous shell. These 9 mm thin plywood panels may not be stiff in itself but in integration with the complete system, it works perfectly to sustain various kinds of stress and loads. The panels are joined with each other using pairs of 835 custom milled MS brackets. Both of these take equal part to form a composite structural system. The shell gracefully sits on four plywood cuboids, which tactfully incorporates all storage and electrical needs of the event along with providing structural anchoring to the shell.

The entire pavilion was assembled by hand following very simple physical rules, piece by piece, by a team of carpenters. After making it completely in Ahmedabad, the structure was dismantled and shipped to Mumbai in 30 arches of 16-28 panels. This allowed for reduction in assembly time and packaging materials. Inspite of the entire assembly being carried out manually, the average dimensional tolerance achieved, was of under 13mm.

The open groves and the etched numbers on each panel neatly unveils the entire construction process. Both of these together, forms the only reference system for the assembly of the pavilion. With no secondary layer to this system, the Pavilion reveals it all for a keen eye.

Right at the back is a common wall shared with another pavilion, along which are placed 150 double sided panels displaying veneers and laminates. The two columns which support the flat end of the shell create space for small meeting and display areas, while the biggest plywood cuboid makes space for a small reception area. The cuboids and the part of the shell resting on them form a canvas to display the various varieties of wood used for their veneers and laminates. The subtle graphical elements all along the pavilion acts a self-guide explaining this part of the design. The yellow LED spot lights adds warmth to the pavilion.

Architect: Studio Saransh

2nd Award – Category: Pop-Ups & Temporary

Project Location: Mumbai

Project Team: Neel Jain, Arihant Bajaj

Country: India